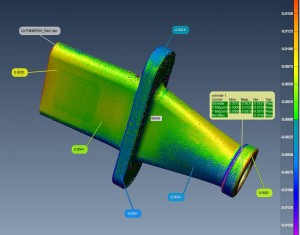

Dimensional Inspection

In the manufacturing industry today, the requirement to dimensionally validate product is not only a quality assurance requirement, it can also be a prerequisite to doing business with many OEM’s. As an A2LA ISO-17025 accredited dimensional inspection and calibration laboratory, Supplier Inspection Services, Inc. understands that your business depends on quality assurance, reliability, and most importantly, consistently accurate information. We have an expansive 5,000 square feet, environmentally controlled laboratory that is amply equipped to support many dimensional inspection needs, big or small. Our diverse capabilities allow us to support a wide array of products and applications.

Dimensional Layout

First Article Inspection

PPAP Inspections

Capability Studies

Gage R&R Studies

Gage & Fixture Calibration

2nd & 3rd Party Certification

Surface Finish

Reverse Engineering

CMM Programming

Brown & Sharpe Global

Travels:

– X Axis = 27″

– Y Axis = 39″

– Z Axis = 29″

Measurement Uncertainty: ± 170 µin + 6 µin/inch

Software: PC-DMIS

Maximum Work Load: 1,500 lbs

Brown & Sharpe Xcel

Travels:

– X Axis = 47″

– Y Axis = 78″

– Z Axis = 39″

Measurement Uncertainty: ± 340 µin + 12 µin/inch

Software: PC-DMIS

Maximum Work Load: 4,500 lbs